Advanced Printing Solutions for Promotional Products & Textiles

- One-stop multi-process solutions, reducing coordination and risk.

- Pantone color matching with strict batch consistency.

- Compliant materials and third-party testing on request.

- Scalable production from small runs to large orders.

Diverse Techniques for Every Custom Product

Heat Transfer Printing

Embroidery

Silk Screen Printing

DTG

Sewing

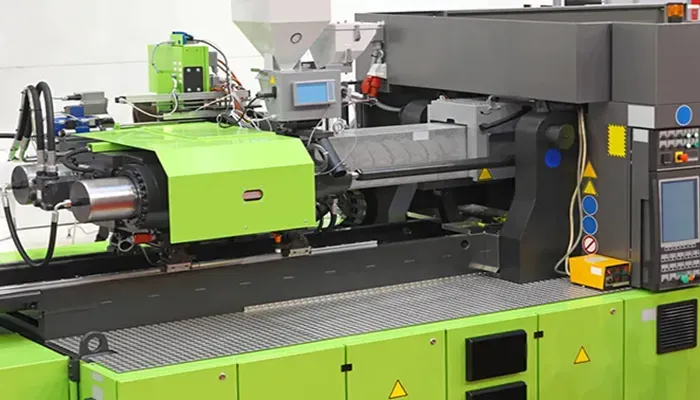

Molding & Injection

In-Depth Process Demonstration

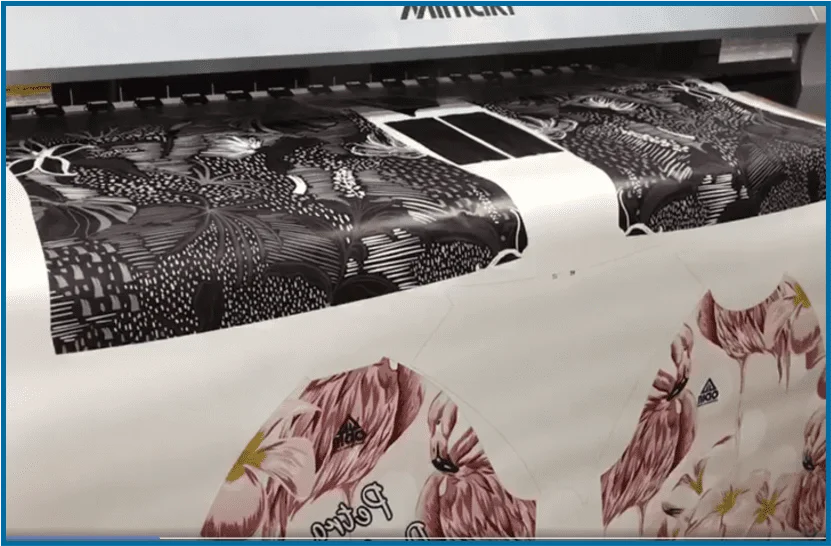

Heat Transfer

Heat transfer is a versatile printing method that uses a combination of high temperature and pressure to move pre-printed graphics onto a substrate such as fabric, silicone-coated materials, or other surfaces. This process allows high-resolution, full-color, and gradient-rich images to be reproduced with excellent clarity. Unlike traditional screen printing that requires multiple screens for each color, heat transfer can easily handle complex artwork, photographs, and variable designs such as names or numbers.

Because of these advantages, heat transfer is frequently used in promotional apparel and accessories—including jerseys, team uniforms, caps, lanyards, and wristbands—where brand owners demand bright colors, consistent logos, quick turnaround, and flexibility for both small and large runs. It is especially valuable in promotional campaigns where personalization (e.g., individual player names, event-specific text) is required without sacrificing efficiency.

Sub-Processes

Heat Transfer Films

Designs are printed or cut onto specialized films (PU, PVC, DTF, reflective, metallic films), which are then heat-pressed onto fabrics. This method is widely used for sports jerseys, caps, wristbands, and lanyards, especially when numbers, logos, or reflective branding are required.

Sublimation Transfer

Sublimation printing uses heat to convert special sublimation inks directly from solid into gas, which then penetrates polyester fibers. The result is a permanent, vibrant, and breathable design that does not crack or peel. Best for polyester-based products such as jerseys, training wear, polyester caps, banners, and fabric-based promotional items.

Strengths & Limitations

Strengths

- Vivid and detailed reproduction – Heat transfer delivers bright, high-resolution prints, handling gradients, fine lines, and photo-quality images that traditional printing cannot easily achieve.

- High flexibility in production – Works equally well for small personalized runs (names, numbers) and large-scale orders, making it ideal for promotional campaigns with variable designs.

Limitations

- Material restrictions – Sublimation is limited to polyester or polyester-coated surfaces, while transfer films may have weaker adhesion on rough cotton or textured fabrics.

- Durability depends on usage – Longevity varies with fabric type and washing conditions; repeated washing or heat exposure may cause fading, cracking, or peeling over time.

Applications

Embroidery

Embroidery uses thread stitched directly into fabric to form logos, text, or decorative patterns. Unlike printing, embroidery adds a premium, tactile, and three-dimensional texture that elevates the perceived value of promotional products. It is widely used in caps, uniforms, sports jerseys, patches, and bags because the designs are durable, resistant to fading, and create a strong brand impression. For promotional campaigns, embroidery communicates quality and longevity—making it ideal for items that are expected to be worn or used repeatedly.

Sub-Processes

Flat Embroidery

The most common type of embroidery, where threads are stitched flat onto the fabric surface. Ideal for logos, text, and simple shapes on caps, uniforms, and apparel.

3D Puff Embroidery

Foam is placed under the stitching to create a raised, three-dimensional effect. Frequently used for bold cap logos and emblems where visibility and tactile impact are important.

Appliqué Embroidery

Combines fabric patches with embroidery stitches, allowing for large designs without fully covering the surface in thread. Used for jersey numbers, patches, and decorative pieces on bags or apparel.

Strengths & Limitations

Strengths

- Premium and durable branding – Embroidery adds texture and a professional look, reinforcing brand identity. Stitched designs are highly durable, resistant to fading, and withstand repeated washing or wear.

- Wide application across product categories – Suitable for caps, uniforms, sports jerseys, patches, and bags, ensuring brand consistency across multiple product lines while maintaining a premium finish.

Limitations

- Limited detail and gradient capability – Embroidery cannot reproduce fine details, thin lines, or complex gradients effectively, making it unsuitable for photo-like or highly detailed logos.

- Higher cost and longer production time – Compared to printing methods, embroidery typically costs more and requires more time, especially for large, intricate, or multi-color designs.

Applications

Silk Screen Printing

Silk screen printing is a traditional yet highly reliable method where ink is pushed through a fine mesh stencil onto the product surface. Each color requires a separate screen, making it especially effective for spot colors, bold logos, and simple graphic designs. This technique is widely used in promotional products because it offers excellent durability, strong color saturation, and cost-effectiveness for bulk orders. It is particularly suited to T-shirts, jerseys, lanyards, wristbands, and flat silicone/PVC items where consistent branding is key.

Sub-Processes

Single-Color Screen Printing

Involves one screen for one color, ideal for logos, slogans, or simple graphics. Widely used for T-shirts, tote bags, lanyards, and wristbands.

Multi-Color Screen Printing

Uses multiple screens aligned precisely to reproduce multi-color graphics. Commonly applied to apparel (e.g., jerseys with multi-color logos) and promotional items that require bold, colorful branding.

Strengths & Limitations

Strengths

- Durable and cost-effective – Prints are highly resistant to wear and washing, making it a reliable option for large promotional orders at a lower unit cost.

- Bold, solid colors – Ensures strong color saturation and accurate Pantone color matching, ideal for brand logos and corporate identity.

Limitations

- Not suitable for gradients or photo images – Best for solid colors; detailed gradients or photographic designs require other methods.

- Setup time for multi-color prints – Each color requires a separate screen and precise alignment, increasing time and cost for complex artwork.

Applications

Sewing & Stitching

Sewing is the fundamental process of using threads to join, reinforce, or finish fabrics and straps. It is indispensable in promotional apparel and accessories because it ensures structural strength, durability, and a neat appearance. In products like jerseys, team uniforms, caps, wristbands, and lanyards, sewing not only provides the necessary support for daily use but also allows for custom details such as contrast stitching or decorative seams that enhance branding.

Sub-Processes

Flat Stitch

Finishes fabric or strap edges with binding or overlock stitches to prevent fraying and improve durability. Often used on lanyards, wristbands, and cap brims.

Edge Binding (Overlocking / Piping)

Finishes fabric or strap edges with binding or overlock stitches to prevent fraying and improve durability. Often used on lanyards, wristbands, and cap brims.

Strengths & Limitations

Strengths

- Structural durability – Reinforces apparel and accessories, ensuring products withstand daily wear and stress points.

- Customizable appearance – Thread colors and stitch types can be customized to match brand identity or add decorative effects.

Limitations

- Labor-intensive process – Requires skilled workmanship, and complex stitching patterns may increase production time.

- Not decorative for fine graphics – Unlike printing or embroidery, sewing is primarily structural and less suited for detailed logos or artwork.

Applications

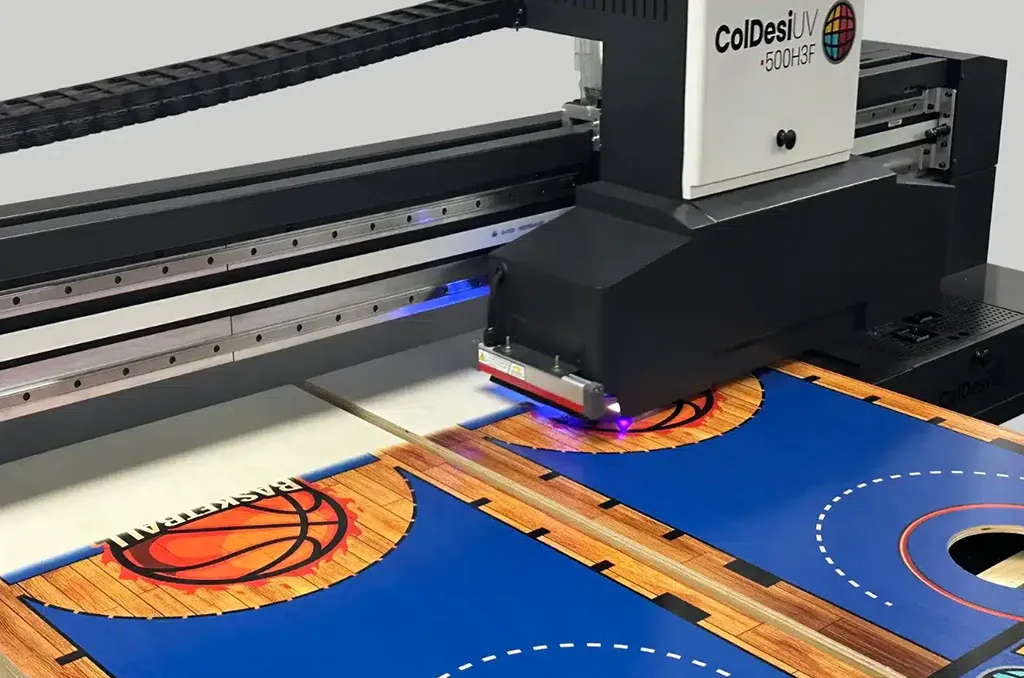

UV Digital Printing

UV digital printing is a modern technique that uses UV-curable inks applied directly onto a product’s surface. The inks are instantly cured by ultraviolet light, creating a durable, high-definition print. Unlike traditional printing, UV printing allows for direct application on flat, curved, or rigid surfaces such as acrylic, metal, coated wood, or silicone-treated materials.

This makes UV printing especially popular in promotional items and hard goods like keychains, mugs, bottles, signage, and decorative home products. It is valued for its ability to produce full-color, photographic-quality images, add special effects such as white ink underlays or glossy varnish, and maintain excellent durability even under frequent handling.

Sub-Processes

Flatbed UV Printing

For flat rigid items such as acrylic keychains, signage, wooden plaques, or metal tags.

Rotary UV Printing

Uses a rotary attachment to print on cylindrical objects like bottles, mugs, and tumblers.

Strengths & Limitations

Strengths

- High-definition, full-color results – Capable of printing photo-quality images, gradients, and special effects directly on diverse surfaces.

- Versatility in applications – Works on acrylic, metal, wood, glass, silicone-coated items, making it ideal for promotional gifts and home products.

Limitations

- Material surface requirements – Works best on smooth, coated, or pre-treated surfaces; adhesion may be weak on untreated fabrics or rough textures.

- Higher equipment and ink costs – Compared to traditional printing, UV printing involves more expensive machines and inks, making it less cost-effective arge-volume, sifor ultra-lmple designs.

Applications

Molding & Injection

Molding & injection involves heating silicone or PVC materials and shaping them through custom molds under high pressure. This process creates products with dimensional, tactile, and durable branding effects. Unlike surface printing, injection molding integrates the design directly into the product structure, making it resistant to peeling, fading, or abrasion.

This technique is widely used in promotional products like silicone wristbands, PVC keychains, and 3D logos or charms, because it delivers a solid, long-lasting, and high-value feel at scale. It is especially suited for giveaways that need to be eye-catching, durable, and mass-produced at competitive costs.

Sub-Processes

Embossed/Debossed

Logos or text are raised (embossed) or recessed (debossed) into the material for a bold and tactile effect. Common in wristbands and badges.

Color Filling

Colored inks are filled into recessed areas of molded designs, allowing for multi-color logos or graphics. Often used in keychains and promotional charms.

Multi-layer 3D

Advanced molds create multi-level dimensional effects, giving products a detailed, 3D appearance. Ideal for logos, mascots, or collectible promotional items.

Strengths & Limitations

Strengths

- Durable and long-lasting – Integrated into the product structure, resistant to wear, water, and fading, ideal for high-use promotional items.

- Premium 3D branding – Creates dimensional, tactile logos and designs that stand out, adding value to silicone and PVC products.

Limitations

- High upfront mold cost – Custom molds require initial investment, making it less economical for very small batches.

- Longer lead time – Sampling and production take longer due to mold development and setup.

Applications

Choosing the Right Technique for Your Product

| Process | Suitable Products | Key Features | Sampling Time | Production Lead Time |

|---|---|---|---|---|

| Heat Transfer | Jerseys, team uniforms, caps, wristbands, lanyards | Bright colors, supports gradients & photo-quality prints, ideal for personalization (names/numbers) | 3–7 days | 10–20 days |

| Embroidery | Caps, uniforms, jerseys, patches, bags | Premium textured look, durable and fade-resistant, strong brand impact | 5–7 days | 12–20 days |

| Silk Screen Printing | T-shirts, jerseys, tote bags, wristbands, silicone flat items | Cost-effective for bulk, solid spot colors, Pantone matching | 3–5 days | 10–15 days |

| DTG (Direct to Garment) | Cotton T-shirts, mixed-fabric apparel | Full-color, breathable prints, ideal for small runs and customization | 3–5 days | 7–12 days |

| UV Digital Printing | Keychains, mugs, bottles, wooden/metal/acrylic items | High-definition, full-color, supports white ink & varnish effects | 5–7 days | 12–18 days |

| Molding & Injection | Silicone wristbands, PVC keychains, 3D charms | Durable 3D logos, embossed/debossed or color-filled designs | 7–10 days (mold) | 15–25 days |

Quality Assurance & Compliance Standards

1. Sampling & Pilot Runs

Before mass production, we provide sample runs to confirm color accuracy and process details. For larger projects, a small pilot production batch can also be arranged to validate stability and ensure smooth full-scale manufacturing.

2. Third-Party Testing & Compliance Documentation

On request, we can provide third-party testing reports and compliance certifications, covering aspects such as material safety, durability, and regional regulatory requirements. All compliance services are arranged according to specific orders and client needs.

3. Strict Tolerance & Quality Control

We strictly control color variance and dimensional tolerances within industry standards, ensuring every batch aligns with client expectations. All specifications are clearly pre-aligned with customers before production to avoid discrepancies.

Get Started with Your Custom Order

Upload your artwork (AI/PDF/PNG), target material, and quantity.

We’ll provide tailored process suggestions and a quotation within 1 business day.